The Caleres Fabrication Studio is both the physical and conceptual heart of Weil Hall. Students and faculty across programs can execute complex projects using industry-grade tools, including laser cutters, 3D printers and scanners, a large-format CNC milling machine, and virtual reality equipment.

Matthew Branham

mbranham@wustl.edu

First Floor, Weil Hall

Equipment

3 Universal Laser Engravers (32 x 18)

3D Printing: 9 Ultimaker S3, 2 Prusa i3 MK3, 1 form3 SLA printer

3D Scanning: Artec Leo, SOL 3d desktop scanner

VR Valve Index

CNC Axyz 4008 (5x8) 3 axis router

Training

In order to use the Caleres Fabrication Studio, students, faculty, and staff must complete appropriate training here.

Using the Caleres Fabrication Studio

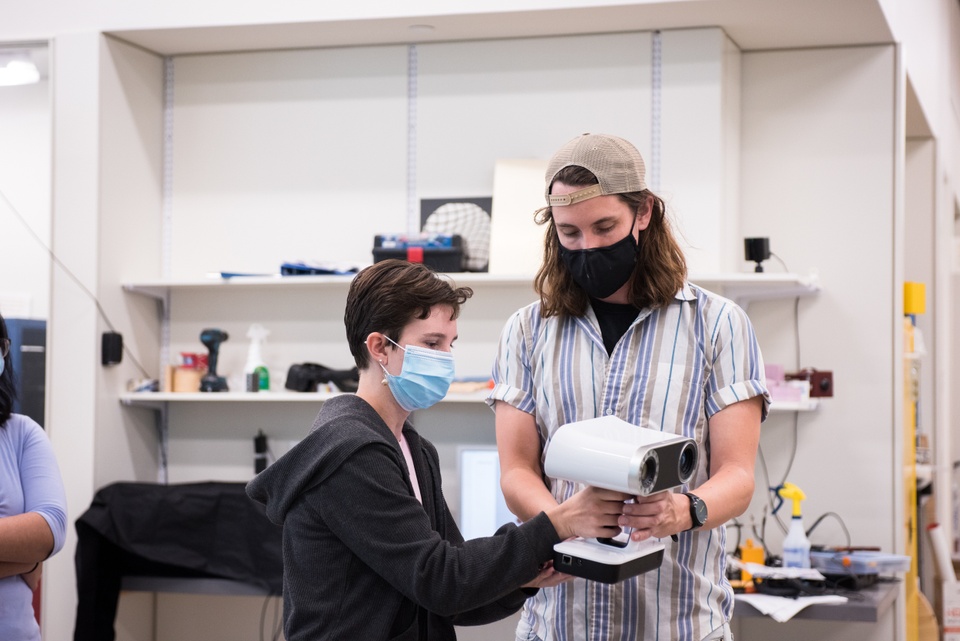

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Exhibit Columbus: Tracing Our Mississippi

Assoc. professor Derek Hoeferlin and students used CNC routers in the Studio to create a large-scale, abstracted model of the Mississippi Watershed as part of his Exhibit Columbus research fellowship.

Using the Caleres Fabrication Studio

Exhibit Columbus: Tracing Our Mississippi

Assoc. professor Derek Hoeferlin and students used CNC routers in the Studio to create a large-scale, abstracted model of the Mississippi Watershed as part of his Exhibit Columbus research fellowship.

Using the Caleres Fabrication Studio

Autonomous Vehicle Testing Platform

Asst. professor Constance Vale employed the Studio’s 3D printer fleet to create a scale model of a city block for testing autonomous vehicle software, in collaboration with McKelvey Engineering.

Using the Caleres Fabrication Studio

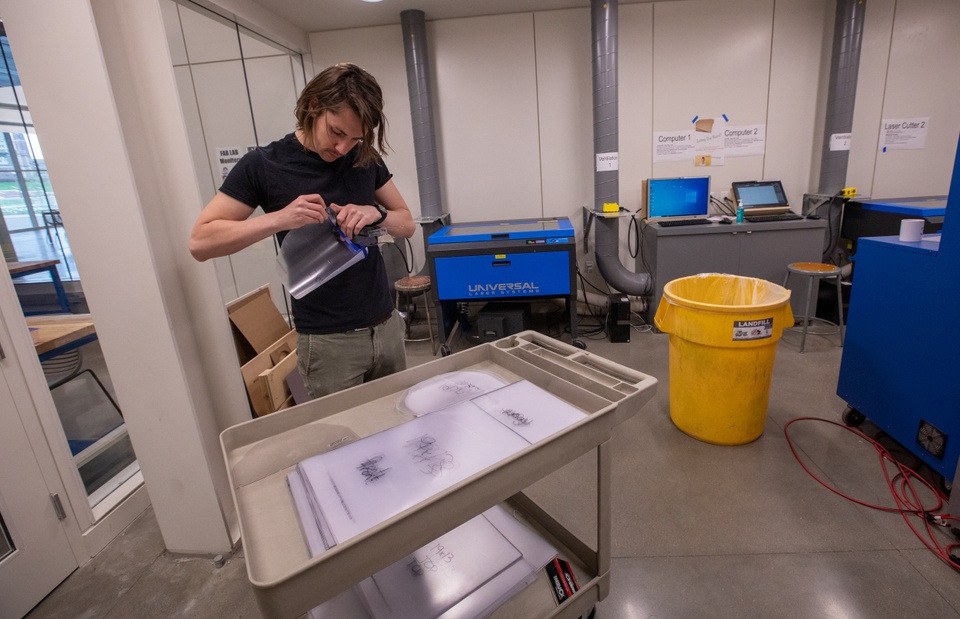

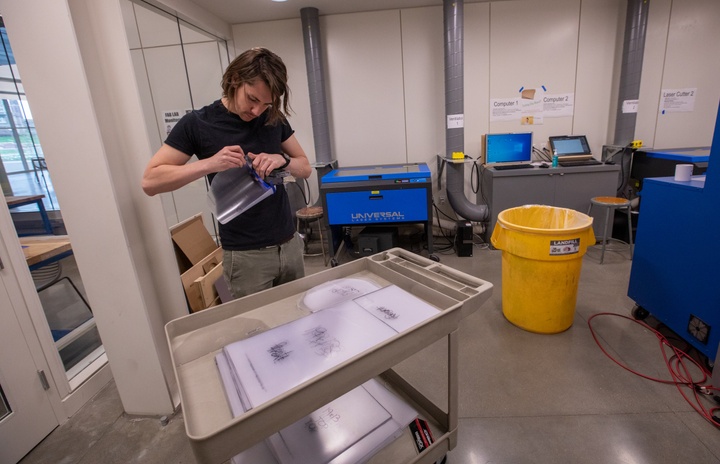

Face Shield Production

Instructional tech Matthew Branham used the Studio’s laser cutters to quickly produce parts for face shields at the beginning of the COVID-19 pandemic.

Using the Caleres Fabrication Studio

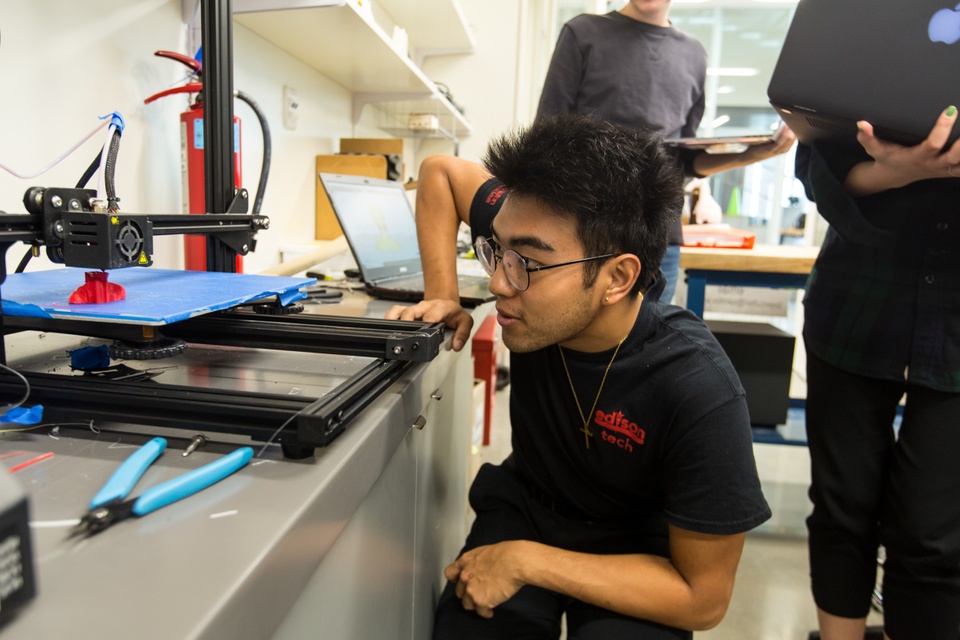

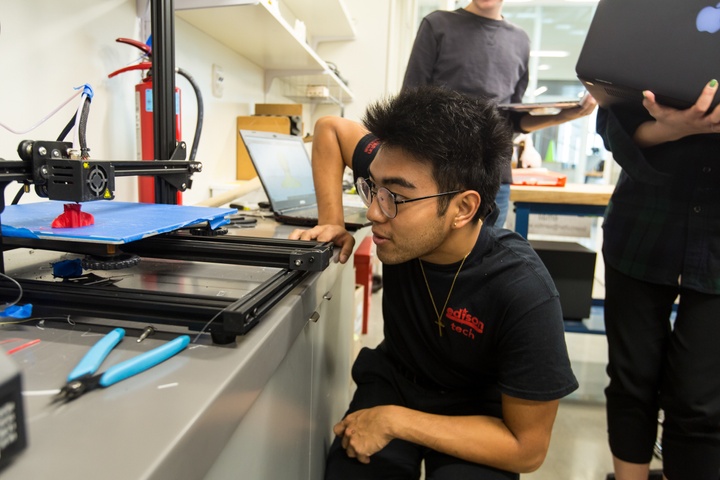

Fox Fridays: 3D Head Scanning & Printing

Students were introduced to 3D printing at this Fox Fridays workshop, where they learned how to scan each other’s heads and create a printable file to send to the Studio’s 3D printers.

Using the Caleres Fabrication Studio

Fox Fridays: 3D Head Scanning & Printing

Students were introduced to 3D printing at this Fox Fridays workshop, where they learned how to scan each others’ heads and create a printable file to send to the Studio’s 3D printers.

Using the Caleres Fabrication Studio

Fox Fridays: 3D Head Scanning & Printing

Students were introduced to 3D printing at this Fox Fridays workshop, where they learned how to scan each others’ heads and create a printable file to send to the Studio’s 3D printers.

Using the Caleres Fabrication Studio

Caleres Fabrication Studio dedication

Washington University dedicated its East End Transformation project in October 2019, celebrating with donors and opening up spaces such as Weil Hall’s Caleres Fabrication Studio to the public.

Using the Caleres Fabrication Studio

Caleres Fabrication Studio dedication

Dean Carmon Colangelo poses with Diane Sullivan, Chairman and CEO of Caleres, in the brand new maker space in October 2019.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Fox Fridays: Digital Design for the Body

Students learned how to operate an Artec Leo 3D scanner to create a digital rendering of their body, then use the Browzwear software platform to design clothing to fit.

Using the Caleres Fabrication Studio

Exhibit Columbus: Tracing Our Mississippi

Assoc. professor Derek Hoeferlin and students used CNC routers in the Studio to create a large-scale, abstracted model of the Mississippi Watershed as part of his Exhibit Columbus research fellowship.

Using the Caleres Fabrication Studio

Exhibit Columbus: Tracing Our Mississippi

Assoc. professor Derek Hoeferlin and students used CNC routers in the Studio to create a large-scale, abstracted model of the Mississippi Watershed as part of his Exhibit Columbus research fellowship.

Using the Caleres Fabrication Studio

Autonomous Vehicle Testing Platform

Asst. professor Constance Vale employed the Studio’s 3D printer fleet to create a scale model of a city block for testing autonomous vehicle software, in collaboration with McKelvey Engineering.

Using the Caleres Fabrication Studio

Face Shield Production

Instructional tech Matthew Branham used the Studio’s laser cutters to quickly produce parts for face shields at the beginning of the COVID-19 pandemic.

Using the Caleres Fabrication Studio

Fox Fridays: 3D Head Scanning & Printing

Students were introduced to 3D printing at this Fox Fridays workshop, where they learned how to scan each other’s heads and create a printable file to send to the Studio’s 3D printers.

Using the Caleres Fabrication Studio

Fox Fridays: 3D Head Scanning & Printing

Students were introduced to 3D printing at this Fox Fridays workshop, where they learned how to scan each others’ heads and create a printable file to send to the Studio’s 3D printers.

Using the Caleres Fabrication Studio

Fox Fridays: 3D Head Scanning & Printing

Students were introduced to 3D printing at this Fox Fridays workshop, where they learned how to scan each others’ heads and create a printable file to send to the Studio’s 3D printers.

Using the Caleres Fabrication Studio

Caleres Fabrication Studio dedication

Washington University dedicated its East End Transformation project in October 2019, celebrating with donors and opening up spaces such as Weil Hall’s Caleres Fabrication Studio to the public.

Using the Caleres Fabrication Studio

Caleres Fabrication Studio dedication

Dean Carmon Colangelo poses with Diane Sullivan, Chairman and CEO of Caleres, in the brand new maker space in October 2019.